Carry a wide range of sizes and grades and specialize in customized small-batch orders

Flexible minimum order quantities

Highly value your feedback, which is essential to our daily operations. Operational speed and efficiency

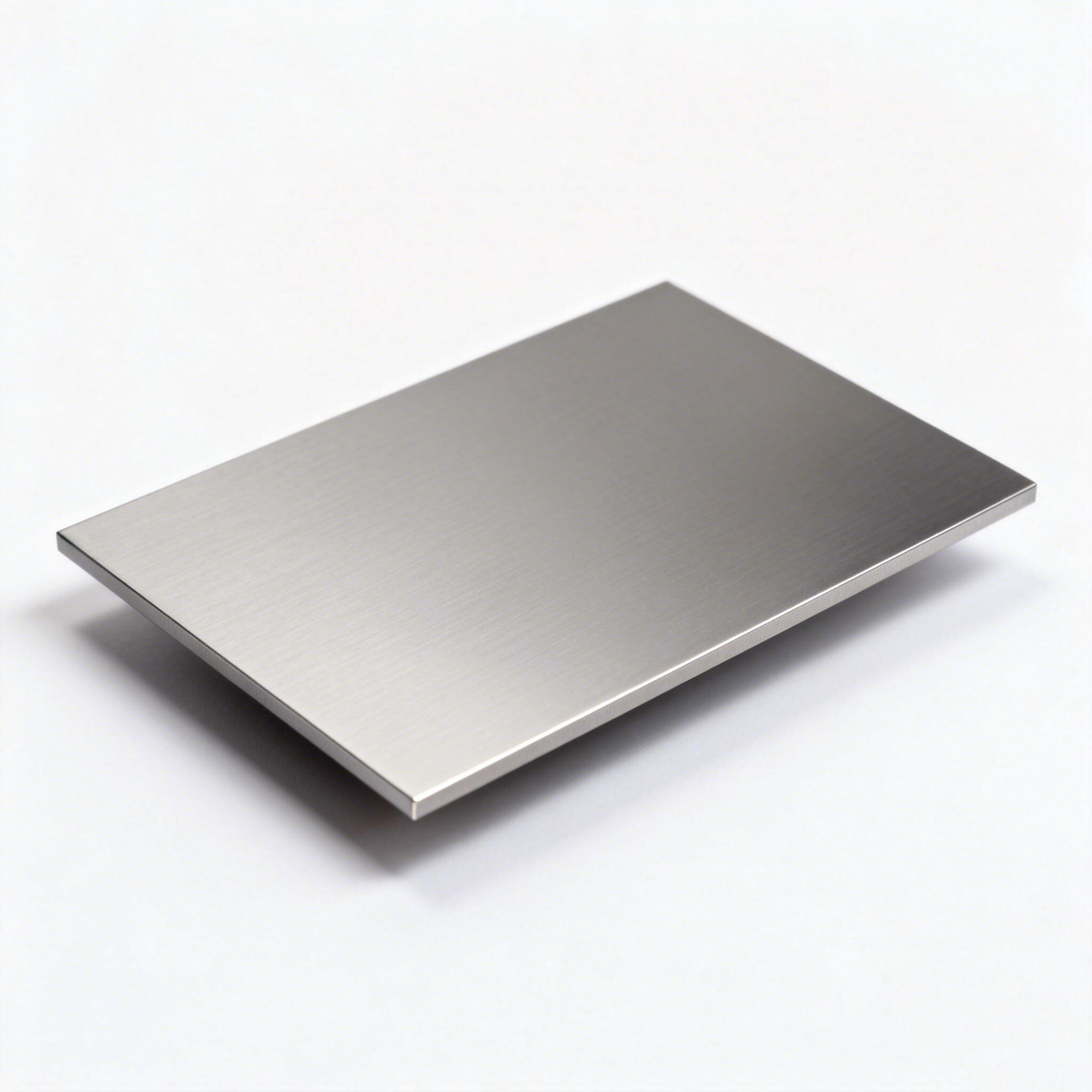

Stainless steel is not a single material but a family of iron-based alloys known for their exceptional corrosion resistance. This property primarily stems from a minimum chromium content of 10.5%, which forms a passive, protective oxide layer on the surface. Among the numerous grades, 304 and 316 are the most widely used austenitic stainless steels. While they appear similar, a key compositional difference dictates their performance in various environments, making the choice between them critical for many applications.

This report provides a detailed comparison of 304 and 316 stainless steel, focusing on their composition, mechanical properties, corrosion resistance, and typical applications.

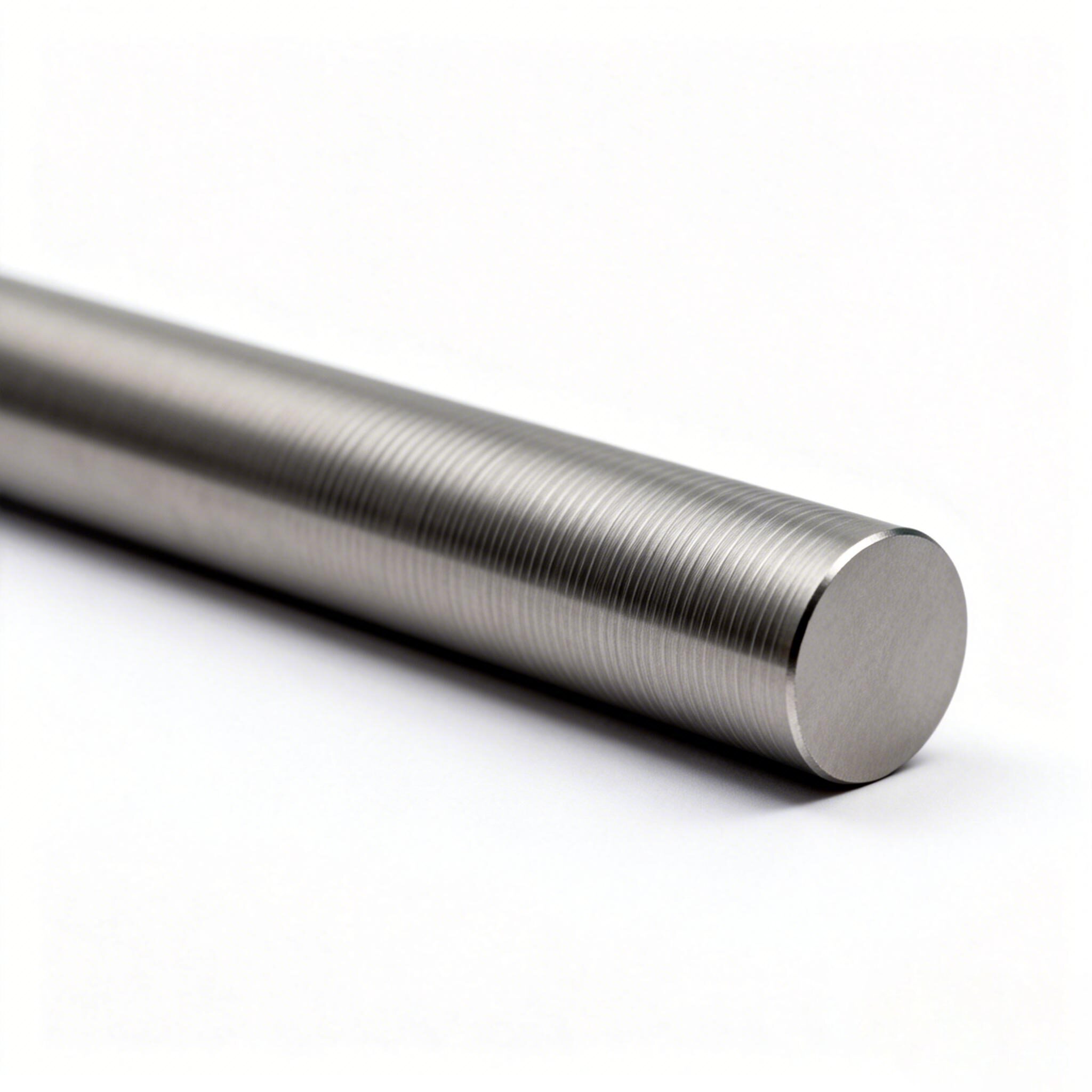

Aluminum, renowned for its exceptional strength-to-weight ratio, corrosion resistance, formability, and conductivity, is a fundamental material in modern industry. Its various forms—plate, tube, and rod—are engineered to meet specific functional and structural requirements across a vast spectrum of applications. This document outlines the primary application scopes for these three common forms of aluminum products.

Aluminum plate is characterized by its flat, rectangular form with a thickness typically greater than 6.35mm (0.250 inches). Its applications leverage its flat surface area, structural integrity, and often its specific alloy properties.

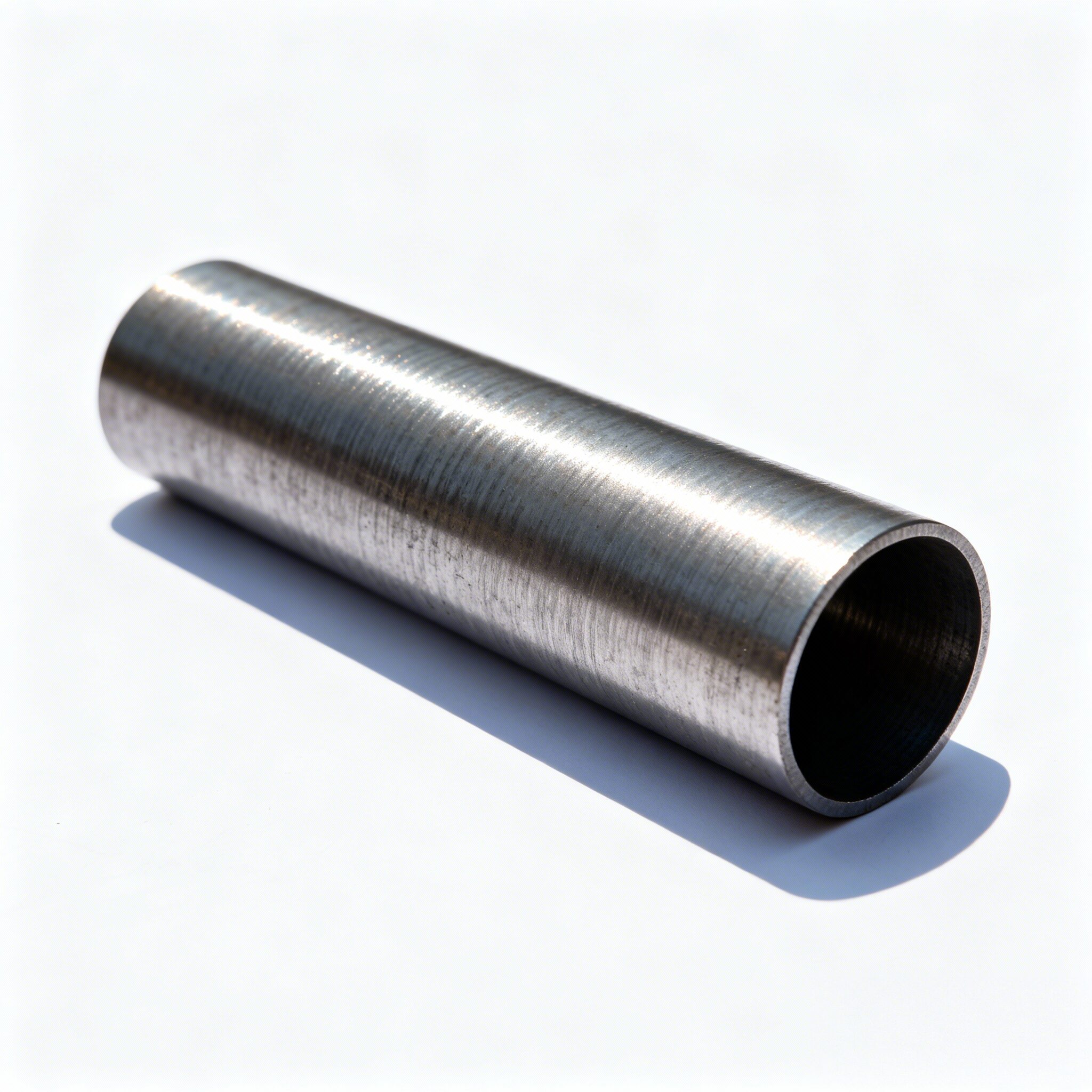

Aluminum tubes are hollow cylinders, defined by their outer diameter (OD) and wall thickness. They are prized for their combination of lightness and strength in structural applications and their efficiency in fluid and gas transfer.

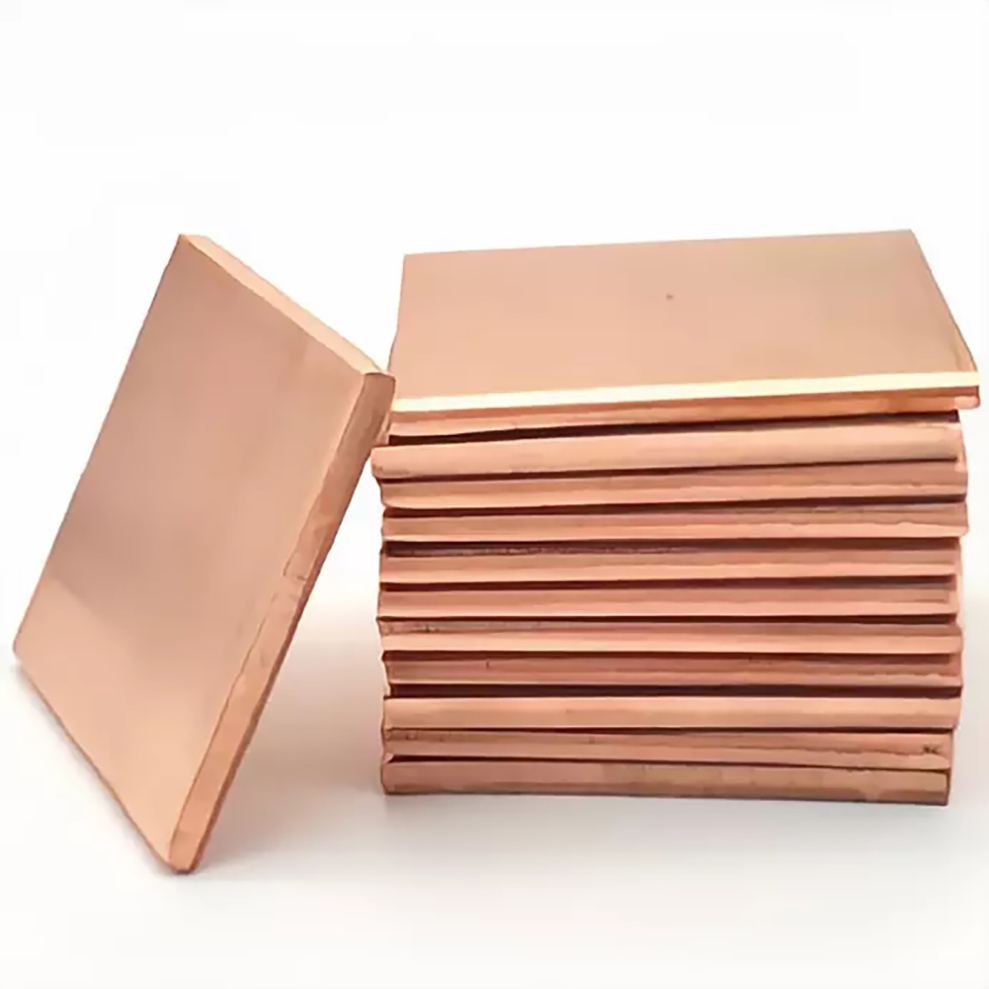

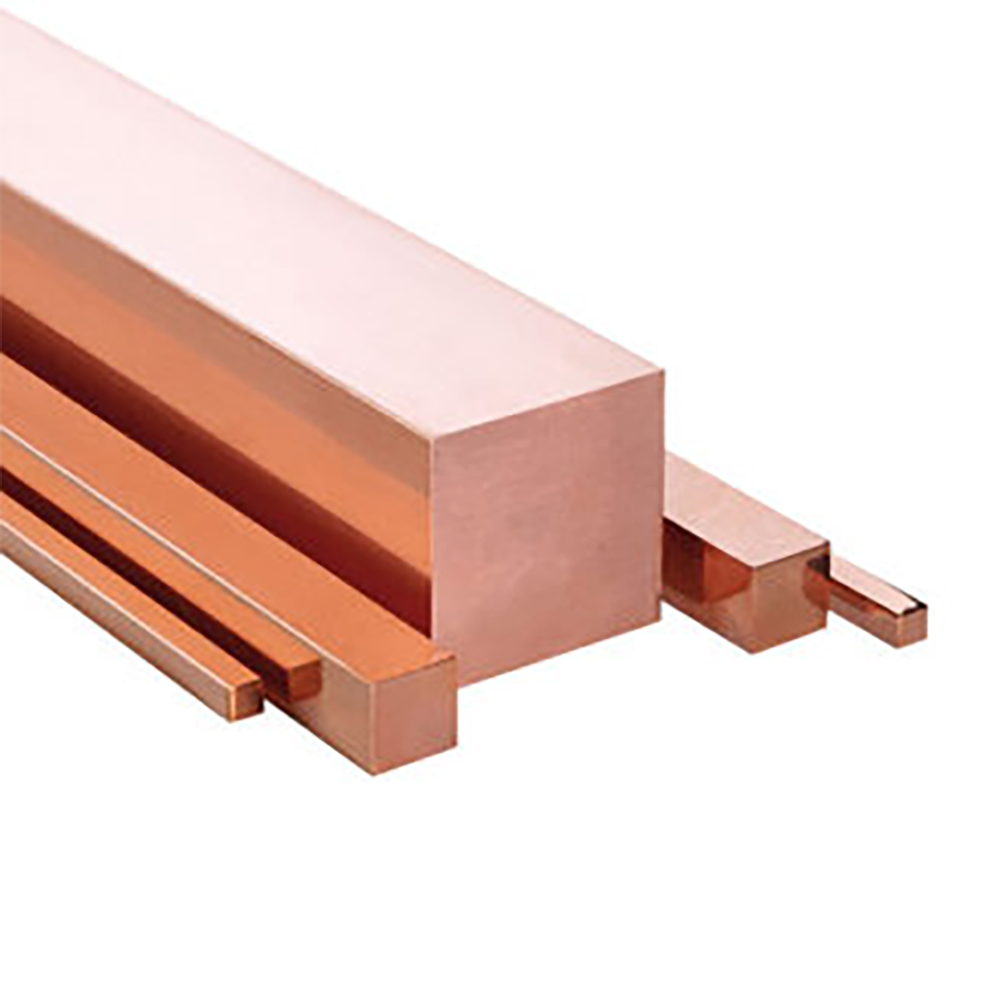

Copper is a versatile metal known for its excellent electrical and thermal conductivity, corrosion resistance, and malleability. It is widely used across industries such as electronics, construction, and energy. Copper can be broadly categorized into pure copper and copper alloys. This document outlines the main classifications and types of copper materials.

Pure copper (≥99.3% Cu) is valued for its high conductivity and is often used in electrical applications. Common grades include:

Copper alloys are created by adding elements like zinc, tin, nickel, or aluminum to enhance specific properties such as strength, corrosion resistance, or machinability.

Brass primarily consists of copper and zinc, offering good machinability and corrosion resistance.