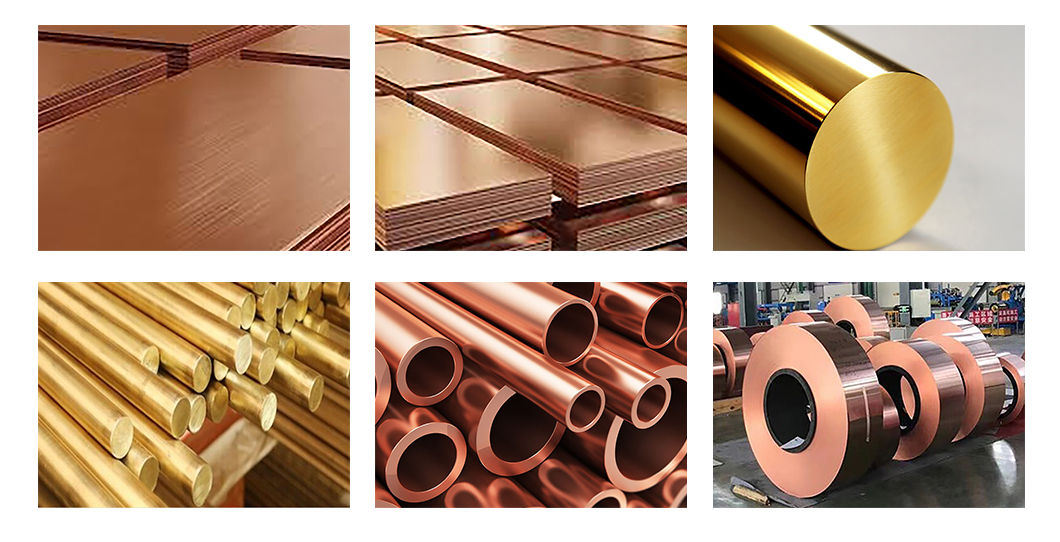

Products

Shape Round Tube

Surface Treatment Polished

Material Type Pure Copper, Brass, White Copper, Bronze

Common Grades T1, T2, T3, Tu1, Tu2, H59, H62, B19, B25

Application Building Hardware, Heat Exchanger Tubes…

Categories: Copper Alloy Series

|

Pure copper

|

|

|

Common grades

|

T1, T2, T3, TU1, TU2

|

|

Characteristics

|

Conductive

|

|

Common uses

|

Electrical switches, motor coils, electronic components, air conditioning piping, soft welding gun heads

|

|

Brass

|

|

|

Common grades

|

H59, H62, H65, H68, HPb59-1 (easy-to-machine brass)

|

|

Characteristics

|

High strength, wear-resistant, resistant to water vapor corrosion

|

|

Common uses

|

Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, military supplies

|

|

White copper

|

|

|

Common grades

|

B19, B25, BFe10-1-1, BZn15-20, BA13-3

|

|

Characteristics

|

Stable physical properties at room temperature

|

|

Common uses

|

Medical equipment, precision instruments, thermocouples, clock parts, eyeglass frames

|

|

Bronze

|

|

|

Common grades

|

QCr 0.5, QCr 0.6-0.4-0.05, QSn 4-3, QSn 6.5-0.4, QSn 7-0.2, QAl 5, QAl 9-2, QAl 10-4-4, QSi 3-1, QSi 3.5-3-1.5, QMn 1.5, QMn 5, QCd 1

|

|

Characteristics

|

Different formulations based on hardness, strength, elasticity, high-temperature conductivity, etc.

|

|

Common uses

|

Lamp spring clips, switch spring clips, resistance welding electrode materials (rolling welders, butt welders, contact welders, riveting welders), chromium-zirconium copper, beryllium-cobalt copper

|

|

CuNi2 NC005

|

1

|

2

|

4

|

6

|

8

|

3

|

10

|

14

|

|

|

CN3W

|

CN5W

|

CN7W

|

CN10W

|

CN12W

|

QMn3

|

CN15W

|

CN20W

|

||

|

TYPE

|

CuNi1

|

CuNi2CuNi4

|

CuNi6

|

CuNi8

|

CuMn3

|

CuNi10

|

CuNi14

|

||

|

NC003

|

NC005NC007

|

NC010

|

NC012

|

MC012

|

NC015

|

NC020

|

|||

|

Composition(%)

|

Cu

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

Mn

|

—

|

—

|

—

|

—

|

—

|

3

|

—

|

0.3

|

|

|

Ni

|

1

|

2

|

4

|

6

|

8

|

10

|

14.2

|

||

|

Max.continuous operating temperatureC

|

200

|

200

|

200

|

220

|

250

|

200

|

250

|

300

|

|

|

μΩ ·m(20℃)Resistivity

|

0.03±10%

|

0.05±10%

|

0.07±10%

|

0.10±10%

|

0.12±10%

|

0.12±10%

|

0.15±10%

|

0.20±5%

|

|

|

×105/℃

(20-600℃) Resistance-temperaturecoefficient |

<100

|

<120

|

<50

|

<60

|

<57

|

<38

|

<50

|

<38

|

|

|

Thermovoltage tocopperat20℃inμV/K

|

-8

|

-12

|

-12

|

-18

|

-22

|

–

|

-25

|

-28

|

|

|

Mean coefficient oflinearthermal expansion,in10/K,at a temperaturebetween20 ℃and400℃

|

17.5

|

17.5

|

17.5

|

17.5

|

17.5

|

18

|

17.5

|

17.5

|

|

|

Thermal conductance at20℃W/mK

|

145

|

130

|

130

|

92

|

75

|

84

|

59

|

48

|

|

|

Specific heat capacityat20℃J/gK

|

0.38

|

0.38

|

0.38

|

0.38

|

0.38

|

0.39

|

0.38

|

0.38

|

|

|

Densityat20℃(g/cm³)

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

|

|

Melting temperaturein℃

|

1085

|

1090

|

1090

|

1095

|

1097

|

1050

|

1100

|

1115

|

|

|

Min.tensile strengthin N/mm²

|

210

|

220

|

220

|

250

|

270

|

290

|

290

|

310

|

|

|

% Elongation

|

25

|

25

|

25

|

25

|

25

|

25

|

25

|

25

|

|

|

CuNi2 NC005

|

19

|

23

|

30

|

34

|

44

|

|

|

CN25W

|

CN30W

|

CN35W

|

CN40W

|

CN50W

|

||

|

TYPE

|

CuNi19

|

CuNi23

|

CuNi30

|

CuNi34

|

CuNi44

|

|

|

NC025

|

NC030

|

NC035

|

NC040

|

NC050

|

||

|

Composition(%)

|

Cu

|

Rest

|

Rest

|

Rest

|

Rest

|

Rest

|

|

Mn

|

0.5

|

0.5

|

1

|

1

|

1

|

|

|

Ni

|

19

|

23

|

30

|

34

|

44

|

|

|

Max.continuous operating temperatureC

|

300

|

300

|

350

|

350

|

400

|

|

|

μΩ ·m(20℃)Resistivity

|

0.25±5%

|

0.30±5%

|

0.35±5%

|

0.40±5%

|

0.49±5%

|

|

|

×105/℃

(20-600℃) Resistance-temperaturecoefficient |

<25

|

<16

|

<10

|

<-0

|

<-6

|

|

|

Thermovoltage tocopperat20℃inμV/K

|

-32

|

-34

|

-37

|

-39

|

-43

|

|

|

Mean coefficient oflinearthermal expansion,in10/K,at a temperaturebetween20 ℃and400℃

|

17.5

|

17.5

|

17

|

16

|

15

|

|

|

Thermal conductance at20℃W/mK

|

38

|

33

|

27

|

25

|

23

|

|

|

Specific heat capacityat20℃J/gK

|

0.38

|

0.38

|

0.39

|

0.4

|

0.41

|

|

|

Densityat20℃(g/cm³)

|

8.9

|

8.9

|

8.9

|

8.9

|

8.9

|

|

|

Melting temperaturein℃

|

1135

|

1150

|

1170

|

1180

|

1280

|

|

|

Min.tensile strengthin N/mm²

|

340

|

350

|

400

|

400

|

420

|

|

|

% Elongation

|

25

|

25

|

25

|

25

|

25

|

|

|

BMn3-12

|

|

|

Alloy Name

|

BMn3-12 (Manganese brass / Manganese bronze)

|

|

Common Grades (Nickel-based alloys reference)

|

Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35

|

|

Chemical Composition (GB/T 5231-2022)

|

Cu ≈ 87%; Mn 11.5–13.5%; Fe 0.2–0.5%; C ≤ 0.05%; Si 0.1–0.3%; P ≤ 0.005%; S ≤ 0.02%; Ni 2–3.5% (Ni+Co total); Pb ≤ 0.02%; Al ≤ 0.2%; Mg ≤ 0.03%

|

|

Physical Properties

|

Density: ~8.4 g/cm³; Melting range: 961–1011.2 °C; Thermal expansion coefficient: 16×10-6 K-1(at 100 °C); Thermal conductivity: 21.8 W/(m·K); Specific heat capacity: 0.408 J/(kg·K); Electrical resistivity: 0.435×10-6 Ω·m; Temperature coefficient of resistivity: 0.00003 °C-1

|

|

Mechanical Properties

|

High hardness and wear resistance with good toughness and corrosion resistance; After quenching & aging: Tensile strength ≥ 400 MPa; Yield strength ≥ 300 MPa

|

|

Application Fields

|

Heavy industry, construction machinery, transportation vehicles, energy equipment, aerospace, automotive; Suitable for heavy-load parts such as bearings, bushings, gears, gearboxes, hydraulic system components

|

|

Processing & Manufacturing

|

Processing methods: casting, forging, extrusion, cutting; Heat treatment: quenching and aging to improve mechanical properties; Good weldability with various welding techniques

|